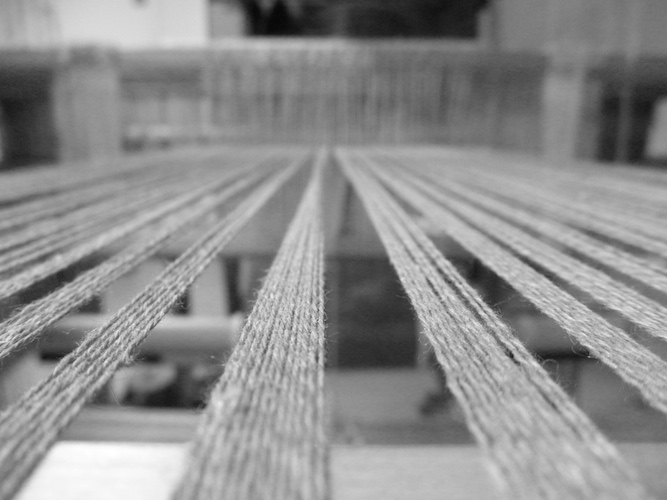

Winding the warp threads

The basic structure of cloth is made up of warp threads. To prepare the warp threads, they are taken from individual spools of thread. Each thread is examined by experienced weavers, in order to ensure that the fabric is of the highest quality.

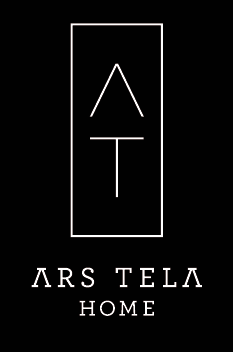

The threads are passed through holes in the warping paddle, so that when the warp is being prepared with different threads, they don't get tangled.

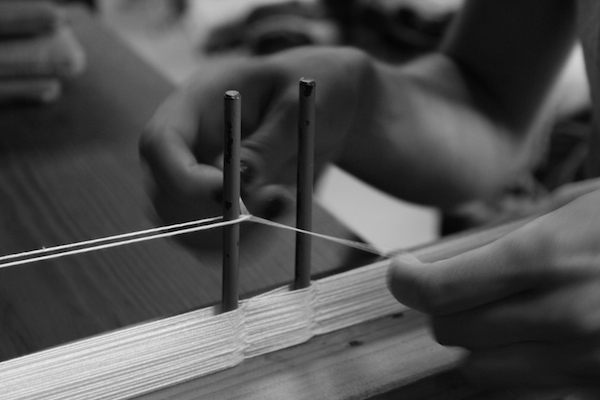

The threads are wound on a warping mill.

When the threads have been wound, the places where the threads cross at the top and bottom are tied carefully with string.

The threads are removed from the frame and plaited together using both hands.

Winding the warp threads takes almost one whole day.

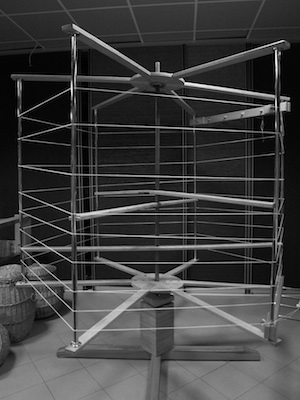

Threading the loom

2-3 people work on threading the warp into the loom.

Setting up a loom for weaving involves a number of tasks: winding the warp, threading the heddles, threading the reed, tying up the pedals, attaching the warp threads. This process can take up to one or two days.

Tying the heddles

Once a year, the weaver themselves must tie the heddles - the loops through which the warp is threaded. This job demands great patience and care of the weaver!

Threading the reed in the beater

Depending on the pattern and density of the cloth, each thread is threaded into the reed in the beater - one thread into one tooth of the reed, which is similar to a comb.

This demands even more patience and care!

Tying up the pedals.

The pedals are like the pedals in a car - they are needed to lift the heddle bar, which lifts up certain warp threads. By pressing on the pedals with both feet, the weaver is able to create patterns in the fabric.

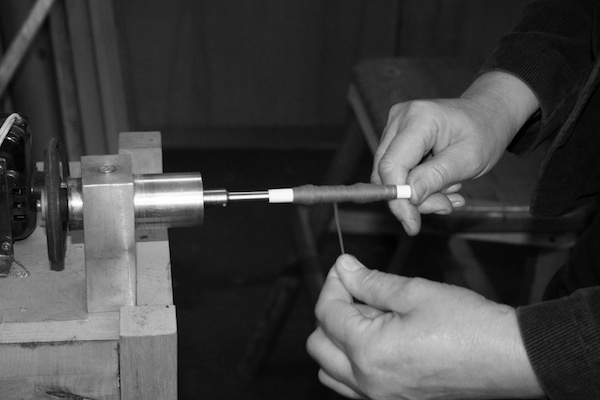

The thread used to weave is wound onto a bobbin.

This is then placed into a shuttle, which is in the shape of a little boat.

Looms and the weaving instruments and tools are often made by specialized craftsmen, they cannot be bought commercially and are not manufactured industrially. Similarly, the husbands and sons of weavers are often involved in helping make bobbin and thread winding machines

Weaving cloth

When weaving, the weaver "weaves with their whole body"

- the legs weave, by depressing the pedals

- the arms weave, by shooting the shuttle through and operating the beater

- the back weaves, when operating the beater. For denser fabrics, more force needs to be used on the beater.

- Occasionally the weaver gets to their feet, to roll the woven cloth onto the roll.

- the brain weaves, thinking about the order and rhythm in which pedals are to be pressed and the beater is to be operated.

A professional weaver can weave around 2 - 3 metres of fabric per day!